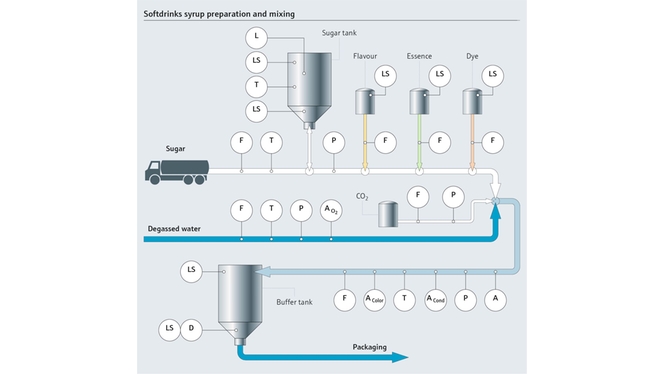

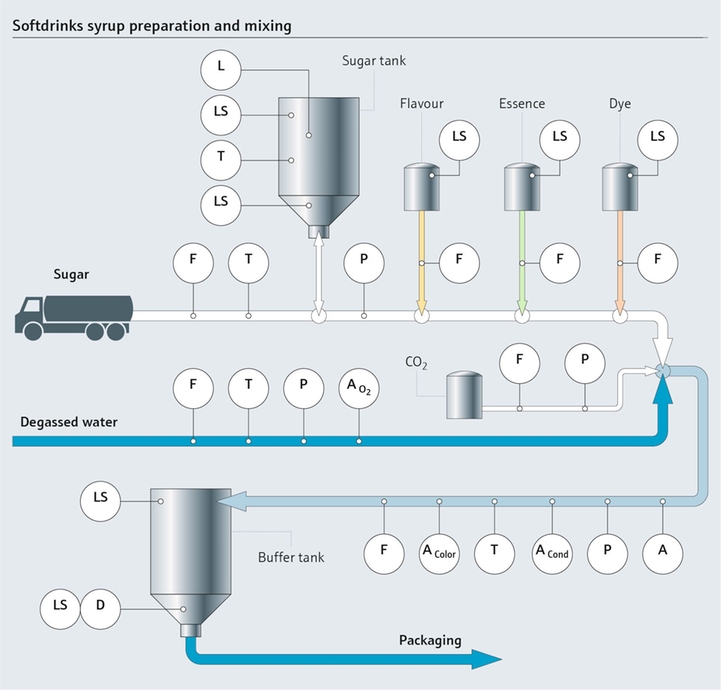

在饮料行业中,稳定的产品质量是重中之重。因此,产品安全、精准原料添加剂量、监测所有关键过程参数、完整数据记录,以及成本意识都是重要的影响因素。创新的过程仪表帮助您应对上述挑战,涵盖从原料输送、添加、至混合和灌装工艺。

关键点

1300 亿升

每年,全球软饮料的消耗量约为1300亿升。始终如一的品质与安全至关重要。 资料来源:www.historyofsoftdrinks.com

投加添加剂

按照软饮料配方正确配料,必须精准的添加配料和添加剂。不仅直接影响产品质量,而且还能有效利用高价值的原料。

我们掌握专业知识

甜味剂、香精、色素等添加剂的电导率较低,需要使用高精度流量计测量。

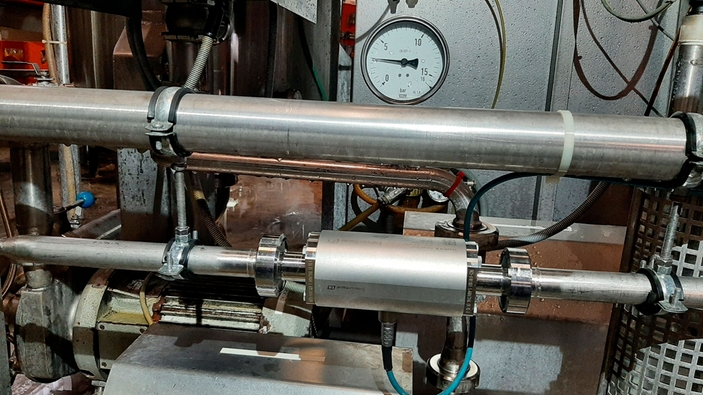

- 选用Proline Promass F 100科里奥利质量流量计,具有高测量精度,搭配超紧凑一体型变送器。

可靠数据管理

完整数据记录是产品可溯源的基础, 对饮料生产过程实施有针对性的监测和优化。

我们掌握专业知识

选用Endress+Hauser的数据管理仪,清晰显示和安全保存过程数据。通过电子签名限制访问权限,实现数据加密管理(符合FDA 21 CFR第11章要求)。

- 按需选择合适的数据管理仪,匹配实际过程和应用需求。

高效相分离

管道内部情况一目了然,杜绝猜测。相分离监测传感器能够精准识别不同最终产物的分界面,区分排放废液和清洗液,或确定介质污染程度。

我们掌握专业知识

即使颜色轻微变化,我们的光学传感器也能精准在线测定液体色度。您可以准确识别管道内的介质,是产品的质量、清洗液,还是冲洗水。

- 选用OUSAF22光学传感器,在可见光光谱范围内高精度在线测量液体的色度。

智能校准管理

食品与饮料行业对食品安全、产品质量和工艺可靠性有严格的法律监管要求,必须定期校准仪表。测量仪表必须符合质量管理体系(比如ISO 9001,HACCP,IFS)的要求,这一点至关重要。

我们掌握专业知识

Endress+Hauser提供无缝可溯源仪表校准服务,既可在现场操作,也可在我们的校准实验室中操作,切实保障产品质量长期稳定,提高了工厂可用性,提升了生产过程的成本效率。

- 查看我们的服务产品,确保关键生产工艺始终合规。

优势

我们竭力为用户提供优化解决方案,保证产品质量稳定,实现高过程和产品安全性。我们的行业专家团队经验丰富,帮助您正确选择测量仪表,并完成选型计算。我们重视发展可持续的客户关系,期待与您携手同行。

关键点

100%

产品安全主要得益于在线质量测量

关键点

30%

选择相分离光学测量技术,实现30%产品节约

关键点

>10%

超过10%的Endress+Hauser全球员工为您提供专业服务

我们的产品组合

Endress+Hauser洞悉严格的行业要求,清楚知晓软饮料制造商面临的严峻挑战。我们提供型号齐全的卫生型仪表,包括流量、物位、温度、压力和液体分析等产品,专门针对食品与饮料行业应用设计、制造和优化。我们的共同目标是:始终如一地提升、保持和确保产品质量和消费者安全。

- 精准可靠的测量技术,专门针对饮料行业的专属要求进行优化。

- 传感器易清洗,全密封设计。最高防护等级可达IP69K,耐受高压和蒸汽清洗。

- 卫生型传感器,符合全球卫生标准,通过EHEDG测试。

- 与食品接触的部件的材质符合FDA “GRAS”、EC 1935/2004和国标GB4806。

- 与各类控制系统无缝集成。