一次性使用技术展现惊人的可持续性平衡

相比可重复使用技术,省去了清洗和灭菌流程,水耗与能耗显著降低

近年来,可持续性已成为企业追求长期竞争优势的决定性因素。新出台的法律法规也日益要求企业减少碳足迹。当然,制药行业也不例外。尽管从可持续发展角度而言,“用后即弃”、“一次性使用”之类的概念具有负面含义,但一次性使用仪表与同等可重复使用仪表相比更具优势。

用户可以选择丢弃或循环再使用Promass U 500的一次性部件,省去原位清洗和原位消毒(CIP和SIP)等复杂清洗工艺。这样可以降低多达40%的水耗和能耗,并且通过取消CIP和SIP工艺还能减少碳排放。因此,从整个价值链的角度来看,制造一次性部件所产生的额外能耗就显得不那么重要了。

©Endress+Hauser

©Endress+Hauser

Promass U 500一次性部分的组成部件:不锈钢测量管、分流器、O型圈

Promass U 500的循环再使用过程的一大优势在于,流量计一次性部分的组成部件的可分离性。这样可以带来以下获益:

- 分流器可与不锈钢管断开,并且可以拆下O型圈

- 一次性测量管的两个包装膜和第二腔室不会接触任何流体,因此可以作为家用塑料循环再使用

- 高压灭菌后,不锈钢测量管完全可以作为废金属循环再使用

©Endress+Hauser

©Endress+Hauser

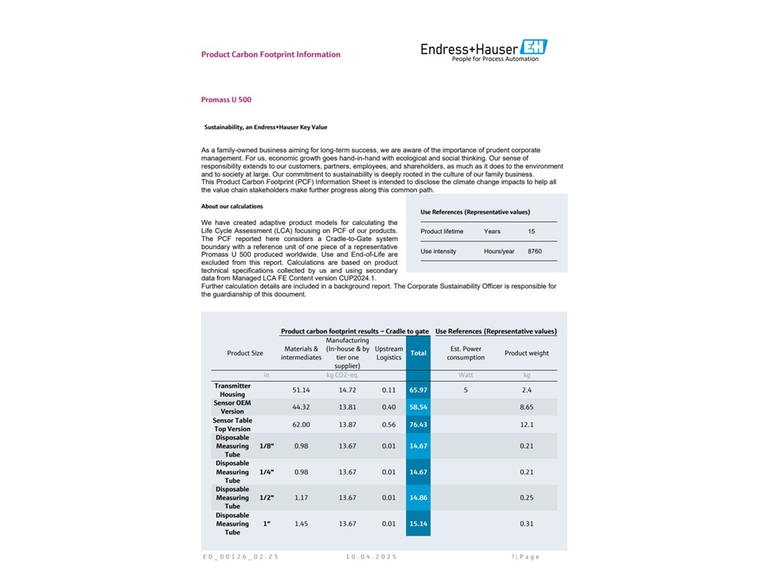

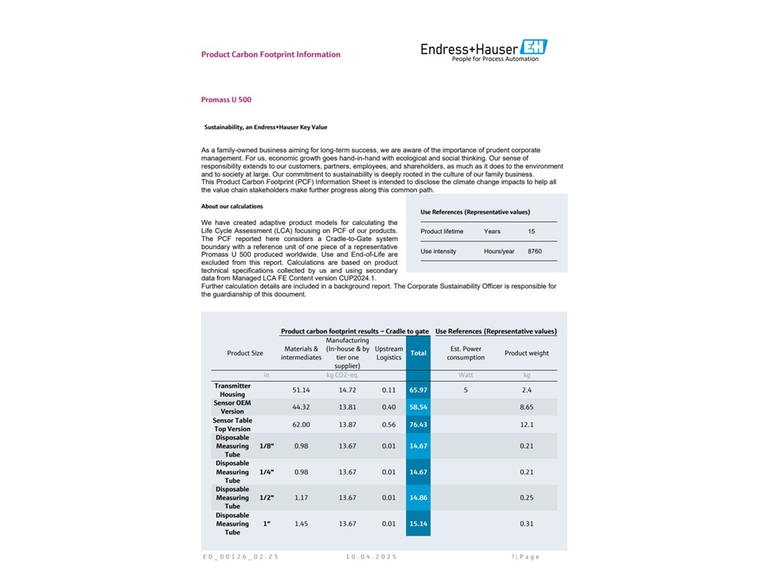

产品在不同生命周期阶段的温室气体排放量有多大?越来越多的企业面临着这样的问题,这也是产品碳足迹(PCF)变得日益重要的原因。Endress+Hauser的可持续发展承诺深深植根于其家族企业的文化之中。因此,每台流量计均在网站上提供PCF信息表,帮助价值链利益相关者在这条共同道路上取得进一步进展。

这种“从摇篮到大门”的PCF方法涵盖从资源开采、部件和成品生产到产品出货的所有流程。本报告不包含产品的使用阶段及报废阶段。

Proline Promass U 500科里奥利质量流量计

Endress+Hauser首款一次性科里奥利质量流量计,满足生物技术应用的高测量精度和cGMP合规生产的要求,最多可以连接4路输入/输出

即插即用

Proline Promass U 500:Endress+Hauser 一次性科里奥利质量流量计,满足生物制药行业高测量精度和 cGMP 合规生产的要求

我们非常重视您的隐私权

我们将Cookie用于提高网页浏览体验、收集统计数据来优化网站功能,以及投放定制化广告或内容。

选择“全部接受”,即表示您同意我们使用Cookie。

更多细节请查阅我们的 Cookie政策 。