Due to its nature of single-use technology, a combined calibration of both components (stationary re-usable base unit and disposable component) is not possible with Promass U 500. These components are manufactured independently and do not undergo joint factory calibration. The first time they are assembled into a complete unit is during on-site commissioning.

This approach represents a paradigm shift in calibration practices compared to traditional technologies. Unlike multi-use flowmeters, single-use sensors cannot be calibrated in-line, as introducing calibration fluids into the flow path would compromise sterility and risk contamination.

The disposable part is typically only used for a short period of time and does not require a recurring check (re-calibration). Instead, Heartbeat Verification is used in the field to confirm the validity of the factory calibration. The base unit will be in operation for a prolonged time (10 years and more) and must be included in the plant’s life-cycle management strategy.

Commissioning with Heartbeat Technology

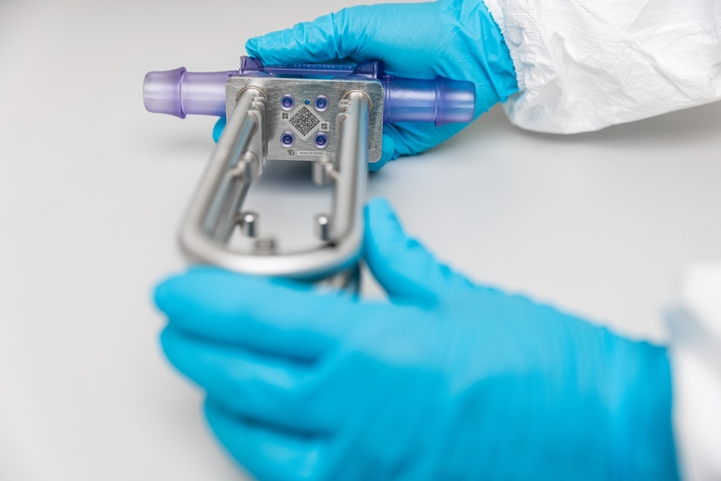

On-site commissioning is typically the first time the base unit and disposable flow tube are assembled into one combined unit. During this process, the Heartbeat Verification procedure not only confirms the validity of the disposable flow tube’s factory calibration, but it also checks the entire flowmeter, including the base unit, the transmitter and the disposable component.

This step is fully automated: each disposable is equipped with an encrypted QR code containing all relevant component information. Once inserted into any base unit, the data set is automatically uploaded into the sensor electronics. The sensor electronics and transmitter settings are adjusted automatically to match the tube set.