乳品行业是利润微薄但质量要求极高的行业。通过优化牛奶加工工艺,我们可以在将产品质量持续维持在较高水平的同时,有效控制成本。其中,热牛奶处理工艺对保障消费者安全和提升工厂效率至关重要。精准创新的测量传感器能确保热处理过程始终处于正确温度区间,并符合各项严格法规要求。

关键点

4000 欧元/年

甚至更多能源损失

超高温(UHT)工艺的温度测量不准确可导致每年高达4000欧元甚至更多的能源损失。 仅比设定值高出两度的温度将会动用不必要的能源,从而产生高昂的额外费用。 采用精确测量技术让一切资源尽在掌控。

我们帮助您

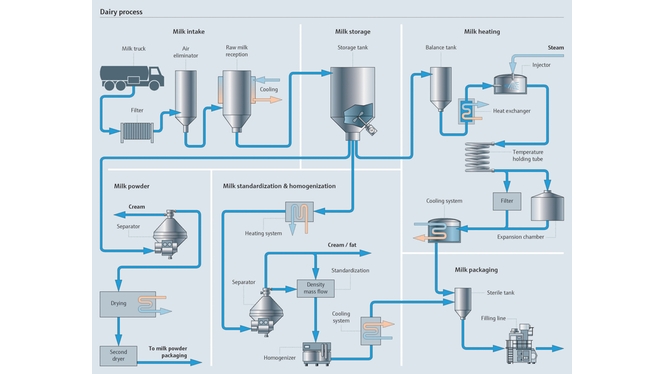

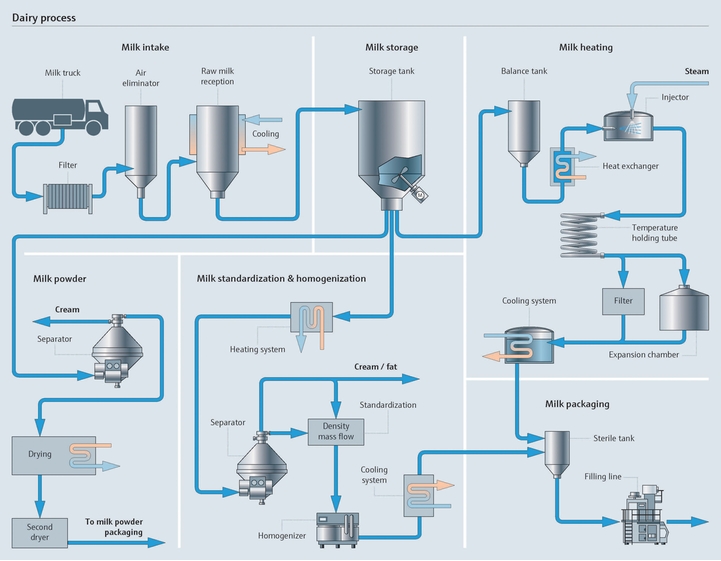

点击流程图,详细了解如何优化乳品生产过程!

选择超短响应时间的温度传感器,优化加热控制

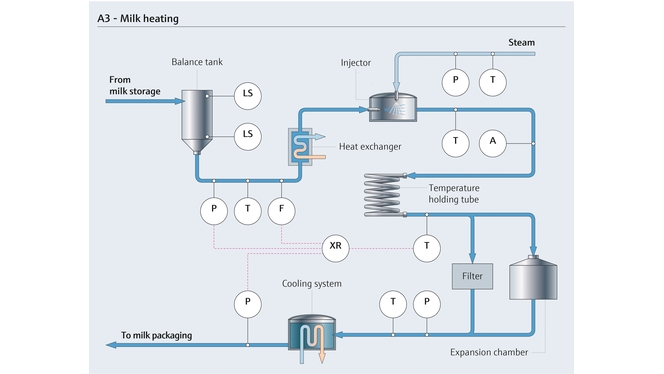

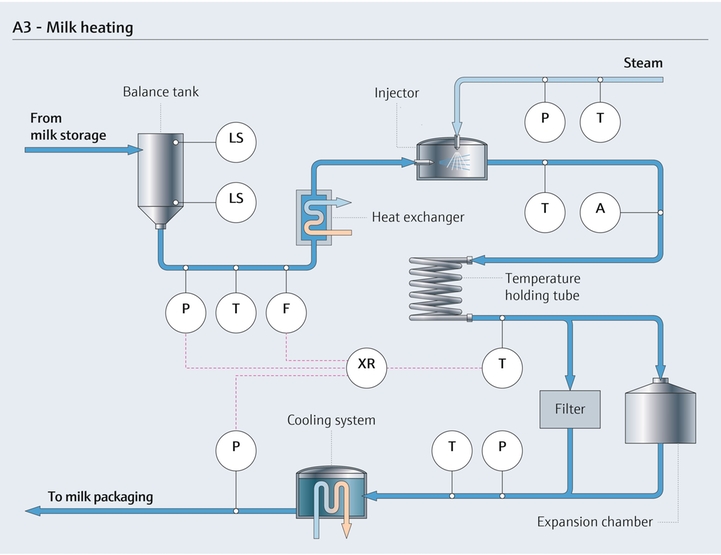

温度是巴氏杀菌工艺的关键控制参数。测量精度和响应时间确保无能量损失,且产品无需负荷不必要的热负荷。

我们的行业专业知识

Endress+Hauser研发出了响应时间非常短的的温度传感器,用于卫生生产工艺。这一创新技术有助于提高产品品质,降低生产成本。此外,精准、快速且稳定的温度测量值是保证高水平的工艺控制和稳定产品质量的基础。

- 安装创新的温度传感器iTHERM TM411,优化改进牛奶超高温灭菌工艺的温度控制。

- 采用iTHERM QuickSens技术,传感器的响应时间非常短(t90 = 0.75秒)。

- 选择iTHERM QuickNeck,显著节省了温度传感器的二次标定时间(每个测量点的传感器标定时间控制在20分钟以内)。

- 使用自标定温度传感器iTHERM TrustSens,降低风险,提升关键工艺的安全性。

牛奶巴氏杀菌工艺的流量测量

高精度流量计确保正确热量供给,保证牛奶安全。

我们的行业专业知识

在乳品加工过程中主要使用电磁流量计进行流量测量,并在牛奶热处理过程中起关键作用。

- Proline Promag H电磁流量计能够同时进行温度和电导率测量。

- Heartbeat Technology心跳技术支持自诊断、自校验和自监控功能,有助于实现工艺优化。

可靠的液位传感器

平衡罐液位控制是牛奶加热工艺中极富挑战性的测量点。小罐体的液位和温度波动较为明显。

我们的行业专业知识

静压液位计是此类应用的理想解决方案。配备温度补偿功能,最小量程可达100mm H2O,完全满足工艺要求。

- 使用分体式Deltapilot FMB50, 能够帮助您降低严苛工况和频繁清洗带来的风险。

- 此外,还可以选用一体式卫生型限位开关Liquiphant FTL33。

换热器两侧的压差测量

为了确保食品安全,必须维持换热器热能回收段冷热两侧的冷热介质的压力差。稳定和可信的测量结果至关重要。

我们的行业专业知识

对于此类严苛工况,建议选用电子差压测量系统。

- 安装创新技术的Deltabar FMD72,优化测量效果。

监测黏附,提升产品质量

乳制品内的微生物浓度对产品保质期和最终产品质量至关重要,通常受法规监管。不仅如此,加热牛奶也会引起设备/管道内壁形成黏附层。黏附会降低加热效率,也可能成为产品染菌的潜在原因。因此,监控整个牛奶热处理过程中的结垢情况,特别是监控最为牛奶热处理关键工艺点的保持管结垢的情况,这是实施过程控制和提升产品质量的关键所在。

我们的行业专业知识

紧凑小巧的Liquiphant FTL43液体音叉限位开关和Liquipoint FTW33限位检测开关能够有效检测工艺异常,如污垢或沉积物。安装在巴氏灭菌过程的保温管上,连续监测黏附状况和结垢程度。这有助于确定是否必须进行清洁处理,在不影响产品质量的前提下是否仍可继续生产。

确保测量结果始终正确

定期维护和校准仪表,确保关键工艺段上安装的仪表始终符合设计规范,为食品安全和品质保驾护航。

我们的行业专业知识

从现场仪表校准到全溯源认证的实验室仪表校准,Endress+Hauser为您提供及时、可溯源、高性价比的维护服务,确保高工厂可用性和仪表合规。我们的仪表校准专家帮助您优化仪表现场安装。

- 选择我们的维护服务,始终保证仪表测量效果,尽可能缩短生产中断时间。

Benefits

Apart from our industry expertise and broad product portfolio, we want to support our customers with valuable process knowledge. We will help ensure that all local and international requirements are met. The promise to be a reliable partner is our goal. We strongly believe in long-lasting relationships with our customers, not just the short range profit.

关键点

0.75 seconds

response time (t90)

iTHERM QuickSens offers the fastest response times in the market for optimum process control.

关键点

3 million

Proline Promag

electromagnetic flowmeters sold since launch in 1977 in a wide range of applications.

关键点

8,700

patents and patent applications

protect the intellectual property behind Endress+Hauser’s products, solutions and services.

我们为您提供的产品、服务和解决方案

Endress+Hauser熟知乳品加工工艺的严苛要求以及面临的严峻挑战。我们为用户提供型号齐全的卫生型仪表,包括流量、物位、温度、压力和液体分析等产品,并专门针对食品与饮料行业进行上述产品的设计、制造和优化。我们共同致力于确保食品安全,保证消费者身体健康。

- 精准、稳定、可靠的测量技术,并对行业专属要进行求优化。

- 传感器易清洗,全密封设计。防护等级高达IP69K,耐受高压水和蒸汽清洗。

- 卫生型传感器,符合3-A卫生型标准,通过EHEDG测试。

- 与食品接触的部件的材质符合FDA “GRAS”、EC 1935/2004和国标GB4806。

- 与各类控制系统无缝集成。

.jpg)